THE COMPANY

Ilary Group manufactures and commercializes hosiery and seamless underwear and outwear for woman and man. The Company headquarter is located in Visano (BS), Italy, in the so called “International Hosiery and Seamless District”.

Private Label Sales are the core of the company business. Ilary has a complete but flexible structure, thus being the perfect partner for each kind of customer. Consequently, its customer portfolio is varied: from the labelled producers willing to outsource a part of their production, to the foreign importers, the big retailers, the specialized chains. Ilary brand is also well rooted in wholesalers and retail stores.

Ilary is proud to offer the label “Made in Italy” to those customers who request it. Partnership is the key word in Ilary Group: in fact, it is through strict collaboration with the customer that you can achieve long-term results.

HISTORY

Born in 1998, Ilary Group inherits the decades of experience of the former Julia Hosiery, founded by Baratti’s family in the early 1960s. Since 1960, our Company works in the textile industry producing high quality tights and stockings.

Over the years, the company has known a constant development and gradual transition from older to the new generations. The new generation, guided by the experience and seriousness transmitted, invests time and resources to keep up with the times.

OUR PRODUCTION

The production cycle is completely verticalized inside the group. Our team takes care of the product from the design concept through all the different production phases constantly monitored by strict and high-standard quality controls. A top quality product is the first step towards the client’s satisfaction.

Knitting

Knitting represents the first and fundamental phase of the entire production cycle. The company owns three knitting rooms: one for the seamless products (underwear, sportive and outwear), one for natural fiber hosiery and one for synthetic fibres. Bobines destinated to knitting our quality department constantly controls the knitted tubes.

Pre-boarding

Pre-boarding is an important step to make the knitted tubes less delicate and easy to handle during the next phases. This process is fundamental on the lighter bases and on the big sizes.

Sewing

During the sewing phase, the raw tubes turn into a pair of tights. The wide sewing room includes machines for manual sewing (overlock and 4 needles, the real flat seam) and automatic sewing. If requested, gusset application is possible. We are able to produce any kind of finishing requested by the customer. A second quality control is performed during this phase.

Boarding

The boarding department is divided into two areas: the electric boarding without steam on empty shapes and the Principe steam boarding on full shapes (both straight and with foot shape). Thanks to these processes, the product is ready to go through the following steps.

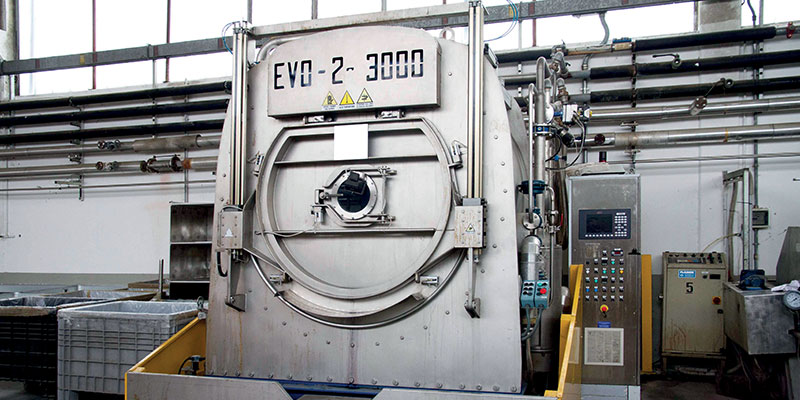

Dyeing House

The Company owns two different dyeing houses: one in Italy and one in Serbia. The first one is focused on the dyeing of seamless products and natural fibers hosiery. The second one is specialized in the synthetic fibers.The Oekotex Certification Standard 100 guarantees product quality and safety. Our dyeing houses have machines for cabinet dyeing and rotatory machines for a dynamic finishing. Centrifuge, tumbler and Stalam machinery are used during drying process. Both the rooms are equipped with a spectrophotometer to allow the control of the color, which is previously visually checked by responsible staff. Fastness, at the base of our dying process, is guaranteed thanks to the respect of Oeko-tex chemical standards. The observance of measures is ensured though the use of specific technical sheets.

Packaging

Ilary Group works almost entirely with Private Label customers, being able to satisfy even the most demanding requests and to respond to strict quality requirements. The Company hires the most qualified staff in the packing of Seamless and fine hosiery products, in order to get a perfect final presentation, corresponding to the specific care that we put in every phase of production.

Quality Control

The Company is committed to respecting all the quality parameters, in every phase of the production process. The final quality control is performed according to the Mil-Standard-105E, Level II, if not differently requested by the customer. This allows our Company to maintain a constant and appropriate quality level, able to satisfy always more demanding customers expectations. At the moment, Ilary Group is working to implement the traceability of the product all along the production chain.

Warehouse

Recently Ilarygroup increased the spaces dedicated to storage and shipment, here goods is put on pallets and secured for shipment.